Construction

As the owner or property manager of a building with an HVAC system, there will be times when you are faced with a central plant or individual equipment that has reached the end of its life cycle, or is simply beyond repair. At this point, Crystal Comfort is there to provide you with viable and cost effective solutions.

We will work with the design engineer of your choice to conceptualize and create plans, estimates and eventually build a new system, or we can perform the project as a turnkey and be your single source.

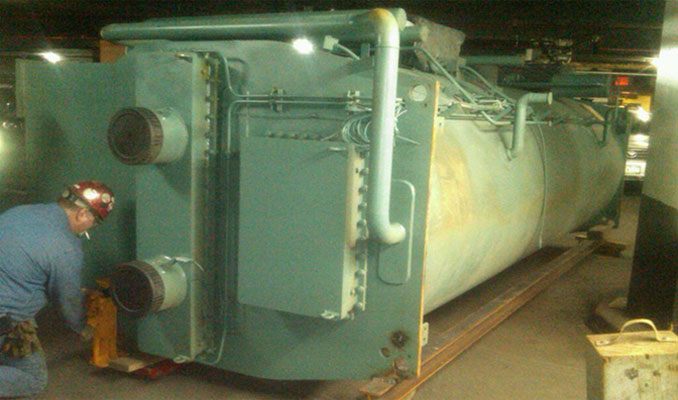

Crystal Comfort maintains the necessary resources to evaluate your building needs and execute a plan for replacement or installation. These include experienced project managers, factory trained technicians, pipefitters, welders, engineers, expeditors, draftsmen, technical documents and software. Our relationships with subcontractors, licensed plumbers & electricians, and master riggers allows us to efficiently manage multiple projects and coordinate rigs, deliveries and commissioning in an industry that is very demanding. We have a network of vendors and suppliers that understand their equipment and application, and work with us to deliver the finished product for clients that expect top performance.

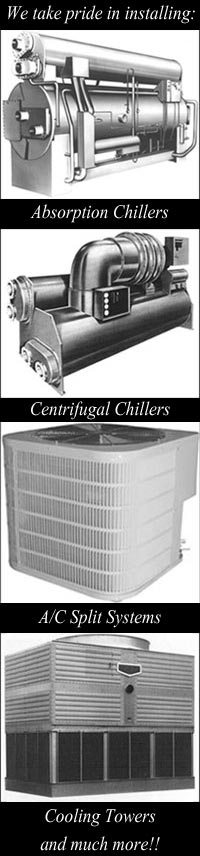

Our strength is in large tonnage central plants. In the past decade no other contractor has successfully installed more new absorption chillers in NYC than us. There is a lot of planning involved with the larger, complex installations and we strive to execute and meet our goals as well as meet your expectations.

After we have successfully completed a Mechanical Construction Project, be it a large design-build, or a simple installation of a single piece of equipment, our Service Groups are ready to take over the maintenance of this equipment and to protect your investment.

History and experience tells us that not every project can be a template of the original building construction. It may not be cost effective or compliant to remain with “50 year old technology”. We have had tremendous success with alternative central plant designs such as: switching central plants from district steam to gas, converting buildings thermal load from steam to hydronic, switching from fuel oil to gas, and upgrading to a co-generation system. We will also collect data on your building profile to calculate performance & energy savings, and do life cycle cost analysis.